Overheated motor oil is losing lubricating oil-this is fraught with premature wear of the engine parts. In case of need to operate the engine in extreme regimes as insurance against overheating, the successful heat exchanger helps. Why the grease may require a cooling radiator

Why the grease may require a cooling radiator

With the increase in the capacity of the automotive engines, engineers have encountered a critical problem of the dissipation of continuously growing excess heat from the engine. The first step towards solving this problem was the emergence of additional cooling ribs on the engine's crankcase. However, it was not possible to solve the problem. Overheated oil was losing viscosity, the pressure in the system was falling, and the driver had to speed up the speed to reduce the heat. Overheated oil lost its properties prematurely: the additives were disintegrating, and the parts of the engine formed sediment. The only way to ensure a large resource was through the efficient removal of heat.

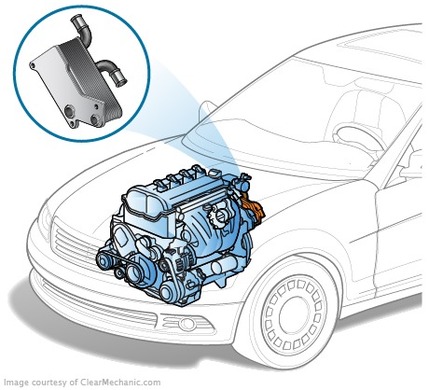

The oil radiator is easy to install as additional equipment

A similar effect in modern cities results in daily traffic jams, so many of the last generation cars have a radiator for motor oil cooling.

The device and operating principle of the oil cooler

Depending on the engineering skills of the manufacturer, the radiator or heat exchanger that is in the cooling fluid environment may be used to cool the oil. The first method is used more frequently on high-speed, high-speed cars, as long as the condition can be calculated on the formation of the flow of the blinking air of great force. This is typically a copper tube snake, sometimes with an additional orebrator, like a cooling system radiator. This heat sink is applied to the Toyota Carina E. lubrication system.

In order to maintain a constant temperature of the oil in the lubrication system, the thermostat shall be integrated with the heat sink. As soon as the engine is started, the thermostat valve is closed and the oil does not enter the radiator. This is necessary to reduce the warm-up cycle of the engine, especially during cold time. In older constructions, a crane was installed instead of thermostat, which the driver could open and close at his own discretion.

The oil radiator in the form of a snake was used in the lubrication system GAZ 24 Volga

In modern designs, liquid cooling of oil is used more frequently. The working temperature of the oil shall be approximately 10 to 20 per cent higher than that of the engine cooling system. The average working temperature of the coolant, even during the summer, is 75 to 80 degrees, and the oil is cooled. If cooling is used, the heat exchanger is combined with the external part of the oil pump to which the oil filter is attached. On the outlet and inlet of the filter, the oil of the canals is in contact with the coolant. Such a decision was applied, for example, to the Renault Megane I with a petrol engine of 1.6 litres or a Nissan CD20T diesel engine installed on the Nissan Nissan Serena.

Benefits and deficiencies of the oil cooler

Aerial cooling of oil is more efficient than liquid oil. But in this case, the system is unwieldy: an additional heat sink and pipework are needed, which are also affected by stones and other mechanical impacts. Another drawback is that at low speeds, with a weak air flow, the efficiency of the system is noticeably worse.

In this regard, liquid cooling looks preferable because antifreeze is constantly circulating in the engine. In addition, the system is much more compact. But it is not suitable for powerful, forced motors, because it cannot effectively cool the oil at high loads. In addition, there is a risk of depressurization between the circuits, and the oil will start flowing into the cooling system. And when the engine stops, the reverse is the oil.

Operation and maintenance of the oil cooler

In liquid-cooling engines, the heat sink does not require any attention and maintenance. Sometimes there can be a leak between the body and the engine block. They must be replaced without waiting for the oil to flow in the stream.

The Masculler is often installed on the "charged" versions of the serial vehicles. For example, the oil radiator is BMW 335i E92, a modification of the 3rd-door series in the body

If you found a dark light on the inner walls, and the liquid itself became emulsion, it might be the thin oil radiator. You can't run a car with this kind of malfunction; otherwise, you will be able to run the motor.

In an air-cooled system, the weak points are the pipes and, indeed, the radiator itself. From time to time, it needs to be washed away, and the debris of the waste is wasted and the heat exchangers degraded.

The oil of the radiator suggests that it has to be repaired or changed. It is not possible to leave this without attention because many cars do not have a safety valve and if all the oil can "run" faster than you notice, it is not a serious repair. Also note the hoses. They shall be flexible and free of superficial cracks. "Suspicious" hoses are better replaced.