The coolant temperature sensor is an important component of the engine management system that controls the temperature of the oB in the refrigeration system. The engine control unit receives information from the DEM and adjusts the composition of the fuel-air mixture, the shaft speed as well as the timing angle. Device and operating principle of the engine coolant temperature sensor

Device and operating principle of the engine coolant temperature sensor

The "parent" of a modern coolant temperature sensor was a thermorel that was installed on certain engines (for example, in a distributed injection K-Jetronic). The contact of the Termorelles is open-the engine is warming up, the contact is closed-the engine is operating in its normal temperature.

The coolant temperature sensor is now a thermistor (resistor that measures temperature-dependent resistance). The control of the temperature of the WO is continuous. The material for the manufacture of thermistor is usually a nickel or cobalt oxide. The peculiarity of these connections is that when they increase the temperature they increase the number of free electrons and consequently decrease the resistance.

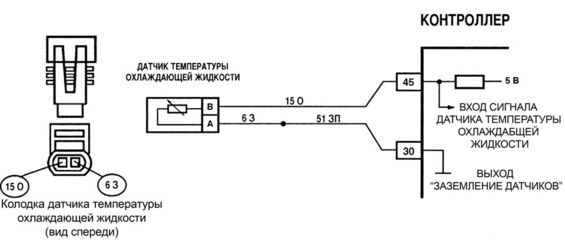

The most common thermistor inside the DTOW is a negative temperature coefficient. The maximum resistance is cold-cold. The temperature sensor of the coolant is supplied with voltage (5V) and is reduced as the resistance changes. The engine control unit records the voltage changes and determines the coolant temperature.

On some engines (for example, Renault engines), a temperature sensor is installed with a positive temperature factor. It works in the same way, but when the temperature rises, resistance does not decrease, but increases. Where the coolant temperature sensor is located

Where the coolant temperature sensor is located

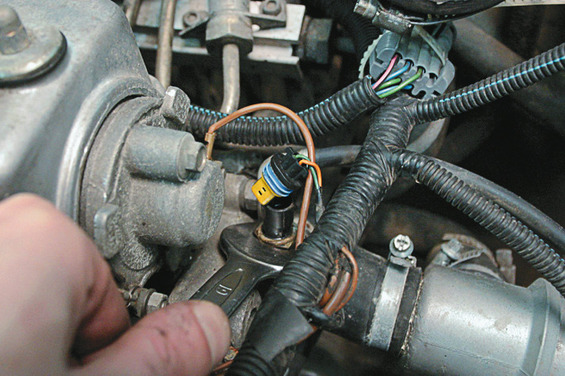

The thermistor is inside the protective thermal conductive enclosure and the rack is located on the sensor and is also an electrical outlet. Usually, the DWY is swayed in the exhaust tube of the cylinder head. There are two sensors on some motors: one detects the temperature at the engine outlet, and the second one is drawn from the heat sink.

The coolant temperature sensor is positioned so that the tip of the coolant is in direct contact with the coolant. Accordingly, if there is little anti-freeze in the system, the DEM figures may not be accurate. Symptoms of malfunction to the DM

Symptoms of malfunction to the DM

As with any other sensor, the DTOP may fail by causing the engine to malfunction. The first signs that can be detected by cooling the coolant temperature sensor are as follows:

- cold start problems,

- in the cold engine exhaust,

- Increased fuel consumption, etc.

Most often, the replacement of the coolant temperature sensor is not required when such symptoms occur. The problem is most likely to be a lost or damaged contact, damage to the transaction, or a coolant leak. Visual inspection of the sensor for damage or corrosion shall therefore be carried out.

Test of the coolant temperature sensor

If the inspection does not produce results, it is necessary to measure the resistance and voltage of the sensor at different temperatures. After the cold start, the resistance shall be reduced (or increased-in the case of positive temperature cut-rate of the sensor) in accordance with normal values.

Normal resistance and voltage for temperature sensor of the temperature sensor of the temperature of the AJ (° C). 4800-66004.00-4.501040003,75-4.00202200-3.503013003,25401000-12002,50-3,005010002,00-2,5080270-3801.00-3801.00-3801.00-1.30110 0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,5-0,

Normal stress and stress values for the LWV with a positive temperature factor