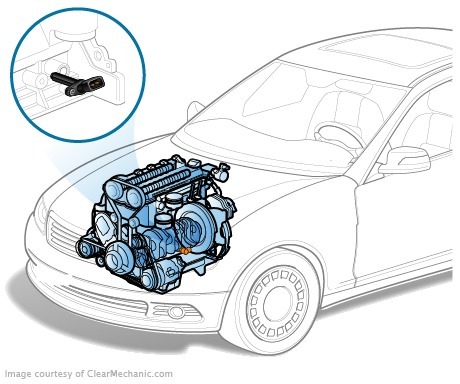

The colenshaft position sensor provides a control unit with information about the position of the pistons in cylinders. Types of shaft sensors

Types of shaft sensors

Magnetic sensor

The operation of magnetic or magnetic sensors is based on the principle of altering the sensitive element due to the external magnetic field. The sensor reacts when passing near the sensitive element of the north or south pole of the permanent magnet. When the action of a sensitive element passes the north pole of the magnet, it is activated and remains in the activated state until the south pole passes by. Then the tie breaker's contacts are blurred to the next side of the pole. The engine control unit interprets this emerging and disappearing signal as an indication of the different position of the crankshaft. A ring of special ferromagnetic material is placed on the crankshaft to control the sensitive element on the crankshaft near which the magnetic sensor is installed.

Different phenomenal properties of materials, exposed physicists, are used as the basis for the wheel operating principle, as in many other automotive sensors

Hall Sensor

The Hall effect is the occurrence of what is called the chollovsky voltage when the conductor is put into the magnetic field. In the case of the knee position sensor, the fixed-current conductor placed in it is placed close to the ring magnetic material reinforced on the end of the cap. The interpretation of the signal by the engine control unit is based on a reduction and an increase in the voltage of the current from the sensor at the points of convergence and removal from the jagged ring.

Irrespective of the design, the engine crankshaft position sensor shall be able to generate pulse signals. They are necessary to determine the current cycle (compression, work and tp), opening of the nozzles and steering angles.

What is the difference between BPM and TPM?

Various brand names can be found in the repair and maintenance manuals of different brands. For example, this may be a DK (crankshaft position sensor) or a NRMM sensor (top-dead sensor). Regardless of the name, it is about the same electrical device, which belongs to the category of pulse or magnetic sensors and the tracking of the knee.

Colenwall position sensor usage considerations

In view of the fact that the dislocation sensor is related to the contactless electric appliances, failure occurs frequently. This is generally due to the degradation of the sensitive element due to reactive substances (oils, salts, reagents, toxic gases, etc.) or a short circuit in the vehicle's side network.

The sensor does not have any mechanical moving parts, so it is rarely available. The most common reason for his refusal was the transaction, which was destroyed by corrosion

The sensor position of the colyenwala "rahrahy" is in itself, that is, working with the variable is not possible. If it fails, this process is non-reverend and cannot be re-enabled.

A much more common occurrence is the gradual partial degradation of the sensor transaction due to the above mentioned negative factors (reagent, salt and thp). In any case, the nature of the malfunction is best investigated by a special diagnostic scanner, which must be in any autoservice.

In case of a malfunction of the sensor on the dashboard of the modern car, "check engine" is lit. If, after diagnosis, it turns out that the case is not in the wiring, but in the sensor itself, you need to replace it.

Can the BCPR be replaced by itself?

The sensor is always attached to the engine's crankcase, to the lower part, usually by means of one or two bolts. Before replacing it, remove the connector from the rear of the sensor. Then, remove the bolts, remove the defective gauge, install a new one in the same position (usually in a different position, just install it), secure the bolts, and return the connector.

After replacing it, you will need to erase the error from the control unit's memory to redeem the alarm "check engine". You must attach a diagnostic scanner to this block.