Despite the difficulties associated with the physical properties of diesel fuel, engines invented by Rudolf Diesel are rapidly winning the market for passenger cars. The cause of this phenomenon is higher than the petrol motors, and the revolutionary development of injection systems in recent years. History of the diesel injection system

History of the diesel injection system

In 1893, a German, Rudolph Diesel, first described and patented the principle of a compression ignition engine and its warm-up heating. It was designed by the inventor to be carbon dust. However, this idea had to be discarded-the particles of coal, which had abrasive properties, were quickly hating the engine. After many improvements in 1897, Diesel was able to build a workable engine in which gasoline was used as fuel.

However, the injection system required debugging-the engine turned out to be very spoky and unreliable.

One of the lucky winners of the cherished license was the Russian businessman Emmanuel Noble. The shortcomings of the new engine had to be rectified. First of all, Nobelya was not satisfied that the engine was working on the road at the time of kerosene. The inventor has given its engineers the task of adjusting the engine for the use of refined oil. But the diesel has not been able to adapt to the peculiarities of this fuel: the details have been overheated and the power was very small.

Bio-ethanol or biodiesel practically differs from oil diesel fuel by color and properties. The main raw material for the production of bio-ethanol-soya, but can be done from potatoes

After several practical experiences, it became clear that diesel engine works well on cheap salt oil-the product of direct oil refining.

At that time, diesel engines were equipped with a fuel feed system based on an air compressor. Noble's engineers modernized her, but she was far from perfect.

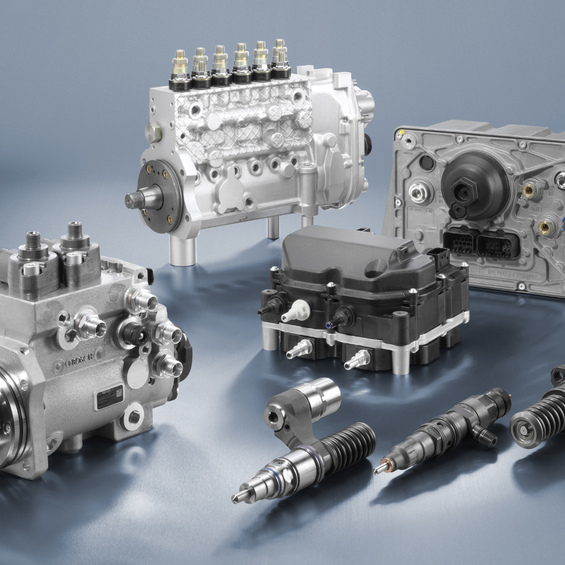

Indeed, a successful and efficient diesel injection system appeared only in the 1920s. It was invented by Robert Bosch, who designed the high pressure fuel pump. The diesel engine has become more hilly, has grown in power and has improved efficiency. Thanks to this invention, the diesel engine starts to gain popularity again.

Vichrecdimensional diesel engine type with injection into a separate compartment where the fuel is preblended with air. Such constructions have experimented, for example, Nissan

The first truck with diesel injection was Benz 5K3, Penta. His motor, the volume of 8.8 litres, produced almost 50 horsepower. And the first passenger car, Mercedes Benz 260D, was released in 1936. Its 2.5-liter four-cylinder diesel engine developed 45 hp.

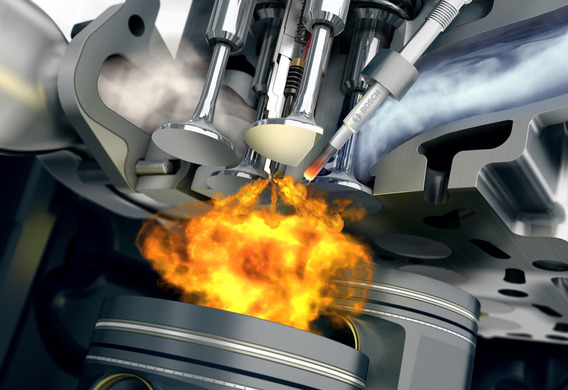

Device and principle of diesel injection

The simplest fuel equipment with a mechanical injection consists of a high pressure fuel pump (TDP), fuel tubes and injectors.

The main element of this system is TDDP. Its task is to supply high-pressure fuel to the nozzle (usually 200 to 300 bar). In order to do this, the pump is used by the pluers, which during displacement drastically increases the pressure in the main line of a nozzle.

Atmospheric diesel engines love the racing fans in SUVs in rough terrain. There is nothing surprising in this: this diesel does not need an electric current

Unlike petrol injection systems, diesel with mechanical nozzle works without electronics. The moment of injection is determined by mechanical tuning and depends on the fuel pressure.

When a certain pressure is reached, the needle shall be raised and the fuel shall be sprayed into the cylinder. When the pressure in the force is reduced, the needle shall be closed and the excess of fuel from the line shall be discharged back to the tank.

The biggest advantage of diesel injection systems upstream of petrol engine injection engines is high efficiency

To date, the mechanical injection has almost completely replaced the improved battery injection Common Rail. In these systems, the injection is controlled by electronics.

Plus and disadvantages of diesel injection

Of course, the biggest advantage of diesel injection systems upstream to petrol injection engines is high efficiency. This indicator on modern diesel engines with accumulator injection, turbocharging and intercooling is up to 55%, while the efficiency of one of the most advanced petrol engines in the TSI series TSI from VW makes up 45%. That is why the diesel has boasted of a very modest appetite.

Specificity of diesel engines with the possibility to develop high torque in the low speed zone. This is the reason why the diesel was used on trucks and buses earlier. In the adaptation of this type of motor for use in cars, engineers had to significantly rework the transmission.

However, the high efficiency of the CPA has a negative side. Diesel-powered dieseles are poorly heated, which makes it necessary for many manufacturers to equip their cars with diesel-fuelled heating systems to operate the heating system of the car.

The use of turbo-boost has given a boost to the use of diesel engines in cars, as it allowed them to achieve comparable dynamic performance with petrol motors

Another problem of diesel injection systems is fuel quality. For example, in Russia it still leaves much to be desired. The main violation is the sale of summer diesel fuel under the guise of winter fuel. The difference can be fatal for winter, as summer salk at negative temperatures can easily freeze, overdrive a car.

Another lack of diesel injection systems is the complexity and high cost of repairs, which can only be performed by a few specialized service stations.

Diesel fuel injection

Vehicle owners with diesel engines should change their filters more frequently. Do not save on spare parts for the repair of the fuel system by purchasing "non-original spare parts". The details of the injection systems are made with special precision, so it is better to acquire original components.