Any engine shall be worn and even deteriorated if wear exceeds the norm. The pistons of the engine, including the cylinders, shall be worn. However, it is worth to bear in mind that the pistons do not always move on a perfectly level path, which means that the wear of the cylinder is uneven and the cylinder loses its shape in time, and the circular profile turns into an ellipsoid. To return the cylinder to its original form, a procedure is used which is called a squabhead of the cylinder block.

There are some basic grounds on which experienced masters determine that the cylinder block needs to be urgently squanded: A change in dimensions of 0.05 mm or more in the upper dead point (the upper piston ring, not piston).A change of 0.03 mm or more at the point where the skirt of the piston and the wall of the cylinder is broken. The "steps" in the upper part of the cylinder, which is broken by the piston rings.

- A change in dimensions of 0.05 mm or more in the upper dead point (the upper piston ring, not piston).

- A change of 0.03 mm or more at the point of loss of the skirt of the piston and the wall of the cylinder.

- Education "steps" in the upper part of the cylinder which the piston rings break.

In any of these cases, it is necessary to waste the cylinder block to return the original geometry and avoid the more serious problems with the motor.

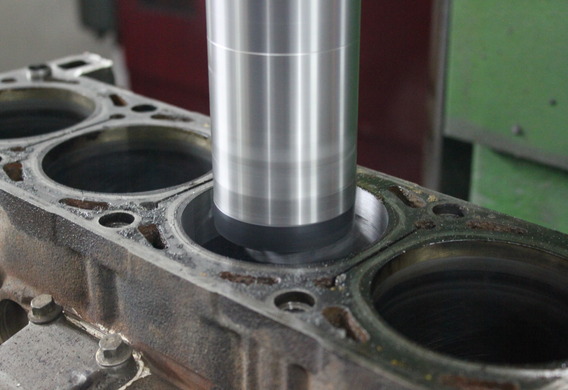

Rastechka of a cylinder block is a rather complex operation and requires a vertically-rawling machine. From the point of view of the procedure itself, the waste is not very complex, but it requires knowledge and skills to evaluate the results of the waste and compare it with what it was before. In addition, micrometric instruments will be needed to assess the condition of the cylinders before and after the waste.

Some car owners are trying to smash a block of cylinders with their hands, inserting a piece of paper into the cylinder. It would seem that it might be difficult to remove the worn layer from the inner surface of the cylinder and create a new surface. However, in fact, the waste of a cylinder block by its hand at home is very difficult, and if the result is incorrect, the result can cause very serious damage to the engine (up to the need for major maintenance).

Once the cylinder has been squelted, another important procedure is to be taken-the onding of the cylinders. The main purpose of the chonings is to reduce the roughness on the inner walls of the engine, to accelerate the burnishing of cylinders with piston rings, and to reduce the wear of the engine parts.

After the chonings on the inner walls of the cylinder the smallest net is formed, thanks to which the oil is better delayed on the walls of the cylinder. The Hongingling of cylinders consists of two stages: first, the inner surface of the cylinders shall be processed by a large abrasier, and then by fine-grained. The most commonly used ones are diamond or pottery abrasive abrasives.