The fuel tank, at first glance, is not simple and uninteresting. However, the specific use of this capacity for petrol or diesel is such that the tank must meet numerous and stringent requirements. Therefore, in the evolution of the car, the fuel tank accounted for many interesting technical solutions. Fuel tank designation

Fuel tank designation

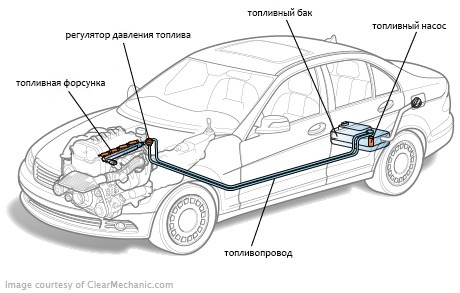

The fuel tank is a leak-proof reservoir containing a flammable liquid which is flammable in the cylinders of the motor vehicle. The tank is part of the vehicle fuel system. The fuel tank is safe because it is equipped with a system to prevent the leak and release of vapor to the atmosphere.

Sports fuel tanks are a reminder of an explosive device or safe. The thickness of walls and design is such that the tank is not sealed even in the case of a series of coups

The main criterion for the reliability of the fuel tank is the complete safety of the contents. This requires, first of all, a material that has a set of properties. Most often, they use aluminium or steel, less plastic. Only high density polyethylene, not sensitive to the effects of aggressive chemical environments and resistant to mechanical loads, is suitable for stamping.

Steel fuel tanks

Steel tanks shall be manufactured by stamping of metal sheets and subsequent welding of the upper and lower parts. For the production of bakov, the steel of high viscosity and resistance to rupture is used. Even if the crash occurred directly into the tank wall, in most cases the gap does not occur. Even a severely deformed capacity remains leak-tight.

Plastic tanks are often used in small cars like Daewoo Matiz, whose body it is important to use every cubic centimeter of scarce space

The main lack of steel tanks is the exposure to corrosion. The probability of falling inside the tank is large enough-it penetrates into the form of condensation or in the mixture with fuel and settles in the lower part of the tank. Outside the bottom, the tank is bombed by a grain of sand flying from under the wheels. However, the manufacturers have long ago found a way out of this situation-tanks are painted from the outside and from the inside, which is capable of protecting even the hull of a ship permanently in the sea water.

Aluminium fuel tanks

Stampoke and welding are made of aluminum tanks. The advantage of this material is that it is not susceptible to corrosion and is low compared to steel weight. The disadvantage is that aluminium welding requires special equipment and skills. Leakage in the case of damage to seams in aluminium tanks is more frequent. The only disadvantage of the aluminium tank is that it can withstand the deformation only once. If secondary deformation is in the same place, the metal is torn. Therefore, if the accident is damaged, it will be necessary to change the tank in any case, even if it is not leak-free: that is the molecular structure of the metal. In addition, the cost of the aluminium tank is higher, and this will affect the price of the car. Aluminium tanks are therefore usually restricted to expensive high-class cars.

Plastic fuel tanks

Plastic tanks have a number of advantages over aluminium and steel. They are free from corrosion and have a low weight. They don't need to be welded in aluminium. However, there can be microleakage, as the plastic is missing hydrocarbons at the molecular level. It is easy to prevent: plastic tanks often do layered, and are covered by fluorine. It is possible to define any kind-and thus achieve minimal use of free space. The plastic tank has been applied in particular in Daewoo Matiz cars.

The fuel pump in the fuel tank does not explode, although electrical wires are connected to it. The petrol property is such that it transmits the electricity freely

Fuel tank design and arrangement

All the tanks shall have the throat through which the fuel is refuelling. The fuel tank is located in the rear of the vehicle and is out through the rear of the vehicle (sometimes other locations). The fuel tank is connected to the tank itself. Outside the throat is released into the hatch with a lid and an electronic or mechanical lock. The opening button is located in the salon; sometimes it can be done in the form of a ginger connected with a steel cable hatch. If the system is electrically open, the lock is fitted with a small electric motor. The loin that provides access to the neck can be located both on the right and on the left. A screw cap is used to seal the throat.

BMW Hydrogen Storage BMW 7 ply tank. Between the layers, 70 layers of special foam are located in a vacuum

In passenger cars, fuel tanks are usually located in front of the rear axle under the passenger seat and are secured by band hammo. In modern vehicles, tanks are often protected from damage by metal sheets. The fuel level in the tank is monitored by a special sensor that is run by a single unit with a fuel pump. However, the sensor is installed separately in vehicles with a diesel or carburetor engine, as the pump is outside. The sensor is a fairly simple device from a float associated with a potentiometer with a metal lever. The placer drops at the moment of the drop in the fuel level, changes the resistance of the potentiometer, and the arrow on the dashboard indicates the corresponding mark.

Why a fuel tank ventilation system?

A certain atmospheric pressure is always maintained in the fuel tank. This is due to the ventilation of the fuel tank. The system disallows extra air that enters there at a gas station and also does not allow the pressure to rise because of heating. Each car has its own fuel tank ventilation system, but all has a safety valve.