The main function of the dissolution is to synchronize the intake and release of engine cycles. In other words, this mechanism is designed for the timely opening of valves and for the combustion chamber of combustion. The moment of opening and closing of the valves on the position of the crankshaft is called the phase of the collapse. Device and distribution shaft principle

Device and distribution shaft principle

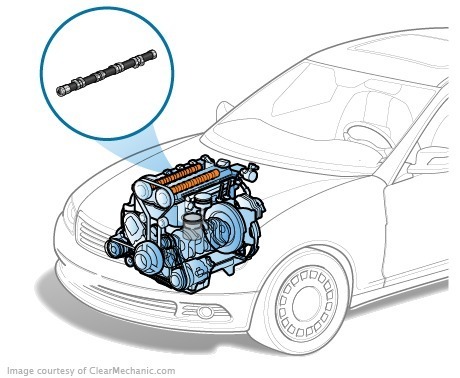

In the modern engine, the breakup (most often the two of them) is located at the top of the cylinder block head.

The distribution shaft is associated with the motor vehicle crankshaft. Connection is done by circuit (or belt) BURMA. To ensure the reliability of the transmission, a slave gears resembling the "asterisk" on the rear wheel of the bicycle was connected to the end of the force.

For the adjustment of the gas distribution phases and the opening order of the cylinders, the quinds of the cylinder shall be adjusted to the maximum number of inlet and outlet valves used in the GRM mechanism. The work is organized in such a position: a cucumper of a preset "runs" to the shutter of the valve, presage it, and opens the valve. Once the pushrod goes off the pushrod, the valve is closed by a tug of return spring.

The larger the valves in the gas distribution mechanism, the more the valves are set up. The Bugatti Veyron four unpreset valves and 64 valves

So, the distribution shaft is rotated so that the intake and exhaust valves are exposed. The position of the coultes relative to each other shall be carefully calculated in strict accordance with the phases of the gas distribution and the firing order of the cylinders. In other words, as long as the intake valve (or two valves) is open, all other inlet valves are at rest.

The engine speed is determined by the configuration of the engine itself: if the engine has a run-of-the-line design and one pair of valves per cylinder, a single design is sufficient. If a single cylinder has four valves, it is appropriate to use two penchens-one of them serves only the intake valve, the other is only the prom valve. Among other things, the system with the paired ramps has another positive-speed.

For V-shaped and oppositic motors, they may have either a single distribution shaft at the place of the so-called "collapse" of the cylinders (the basis of the imaginary V) or two-one at each head of the cylinder block. To try to implement the complex scheme of opening and closing of 16 valves with the help of one is possible, but it is not rational-it will get too complicated. Such schemes are rare, but Honda company has decided to take one of them: a straight engine with four cylinders and one of them has been installed, for example, on the popular Honda Fit/Jazz model. The unconditional dignity of such a system is the ability to make the engine compact and easy.

Characteristics of the break-up

Usually, three important characteristics were adopted: this is the lifting of the valves, the length of the valves and the phase of the valve.

For the maximum period of opening of the valves in the construction of sports motors, engineers dont idling. racing cars are rarely below 2000 revolutions per minute.

The valve rise is measured in millimetres. This measure measures the maximum distance of the valve from the so-called "saddle" in which the valve is located at the time of closure. The duration of the valve opening is the span of time during which the valve remains open. Measure the measure taken in degrees of turn of the crankshaft. At the same time, each of the listed criteria is capable of influencing the engine operation: if the valve is increased, the duration of its opening or the optimization of the gas distribution phases is increased. It is worth noting that the length of the opening is the main parameter with which the designers of forced motors work.

For example, distribution ramps used in sports cars provide long duration for opening of valves compared to standard. This means that the valve remains open for as long as possible, allowing the maximum amount of combustion chamber to burn as long as possible. Unfortunately, the technique for achieving one has to sacrifice something else: the installation of sports crucible does not allow to keep idle speed below 2000 rpm. Naturally, the engine consumes a huge amount of fuel.

In the case of pay-as-you-go phases (when valves are opened and closed down relative to the position of the preset), all information about them is usually contained in the data sheet attached to the distribution shaft. The table shows the angular positions of the distribution shaft as well as the opening and closing of the inlet and outlet valves.

Modern engines are often equipped with systems for changing gas distribution phases. For example, some Toyota vehicles have a VVT-i system. The adjustment of the gas distribution phases occurs by turning the distribution shaft relative to its actualsprocket. Another example is the development of a Japanese manufacturer Honda, which has been given a VTEC symbol, it allows to change the phases using two coulops for the regulated valve.