The automotive air conditioner today switched to ordinary devices: according to ubiquitous statistics, about 3 million cars moving on Russian roads have already been fitted with "in the base".

The air conditioner is not only a high comfort, but also safety in motion. In a car equipped with an air conditioner, the driver is always in the comfort zone, the temperature "baking" does not distract him from driving the car.

Periodicity of service

All the compounds in the air-conditioner are made on rubber seals. Under the influence of the environment and temperature of the engine, the seals have partially lost their properties over time. This leads to the gradual volatilisation of the refrigerant and requires a refuelling of the system after a certain amount of time.

After 60,000. The car air conditioner requires service. Here you need to pay attention to the service!

The automotive air conditioner station requires the appropriate equipment, both for diagnostics and for the maintenance itself. In addition, there is a need for quality filling material (only allowed by the manufacturer) and the most important-highly qualified employees.

Some of the "oumpols" believe that they will be able to replace the gas and oil without having the equipment, but it is time to disappoint them: the refuelling of the automatic air conditioner is slightly different from the refilling of the lighter for cigarettes. Unprofessional activities will ultimately be a costly visit to the service. The air conditioner is responsible and complex operation, any non-professional intervention reduces the operational life of the air conditioner and leads to the premature exit of the auto-conditioner.

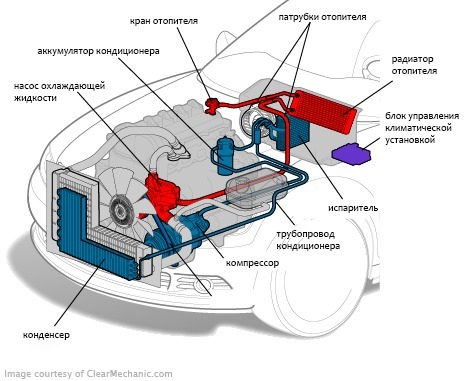

With all the apparent simplicity of the auto-air conditioner, besides the complex equipment, the knowledge of its internal structure and understanding of the principle of its operation is required.

Air Conditioning Service Order

The scheduled service performs diagnostics of the air conditioner, its refuelling, replacement of oil and necessary preventive maintenance.

After the repair of the air conditioner after the airtightness of the air conditioner, or in the case of emergency depressurization, the system is inimably saturated with air. In addition, a certain amount of moisture enters the system, leading to hot spots (especially compressor valves).

In addition, the air conditioners in the air conditioner may be able to freeze at negative temperatures in the air conditioning system and to close the section of the thermoset valve (TRV).

The presence of air in the system also affects the operation of the air conditioner. The air of 70% is saturated with nitrogen, which has different physical properties, which gives an unnecessary burden on the compressor.

To rid the system of air and moisture, the system shall be evacuated. The vacuum unit is also fitted with a dehumidifier filter from various pollutants.

In addition, auto-services are equipped with refrigerant detectors that detect leaks in any inaccessible locations. The sensors are a modern instrument that includes a microprocessor with a highly sensitive semiconductor converter. Complex electronic filling allows detection of refrigerant leakage up to several grams per year.

Air conditioner Loading

After the system has been tightness restored and its evacuation is evacuated, the air conditioner is directly loaded. The stable operation of this instrument is possible only if the regulated quantity of gas is strictly regulated.

Today, depending on the equipment, there are two ways to control the dosing of the gas being supplied: using a tube or by electronic balance.

The use of the measuring flask at a gas station gives you the opportunity to visually monitor the amount of gas on the graduated scale on the gas. When the necessary volume of gas is obtained, the valve is opened and the gas starts to leave the flask into the air conditioning system. The gas output continues until the pressure in the system and the bulb is levelled. To squeeze out the remains of the gas from the bulb, it is fitted with a heating element. When heating is activated, the gas starts to expand, the pressure rises, and it goes into the system.

If there is a reverse line port, the air conditioner itself can pump the gas with its compressor. When there is a zoom in the system, the process of charging the air conditioner can be controlled visually.

When you need to add the missing quantity of oil to the compressor, it is refueling using the special injector.

Today, there are fully automated air conditioning units with refrigerant, where all operations are performed automatically, according to the pre-selected software for the car brand.

Why is the exact dosage of the freon so important?

The working body of the air conditioner is a compressor, for which a certain level of oil has to be maintained as in the car engine. The compressor runs the freon through its working cavity, and the gas is grasping some of the oil and transferring it to the system. At normal level, the mural portion of the oil is continuously circulating through the system and returned to the oil crater without affecting the compressor.

At the insufficient level of the freon (manual refuelling, sealant leak and so on), the compressor starts working in the oil-fasting mode. The air conditioner ceases to be "cold", but the main danger is not this, but the significant reduction in the life of the compressor.

The reloading of the freon also affects both the operation of the air conditioner (not "cold") and the operation of the compressor. The increased amount of freon is leading to higher pressure in the system, and the compressor is forced to operate in limitless mode, sometimes until the emergency stop.

What oils and refrigerants should be used?

It should be added to the above that only the refrigerant and oil recommended by the manufacturer should be used for air conditioning. In addition, each refrigerant is compatible only with a certain type of oil (not including a universal mass of oils compatible with any freon). Let' s say that the previously used freon R12 is only compatible with mineral oil, and the modern analogue of R134a can only operate with synthetic oil.

Until the mid-1990s, the refrigerant for air conditioners was a freon of various brands, mainly freon R12. With the moratorium on the prohibition of the preparation and use of freons damaging the planet's ozone layer, since 1993 the freon was replaced by a refrigerant R-134, which has no chlorine.

In Europe and the US, it is forbidden to even repair auto-conditioners using freon as a refrigerant. Today, the Freon R12 produces and uses only China, which signed an agreement on the complete cessation of its production and use in 2014.

Refrigerant R134 is a colourless gas, does not ignites and is not toxic. Since the R134 has no smell or color, it adds a special fluorescent substance that helps to determine its leakage by means of a UV lamp.

It is important to remember that the freon R12 and the R134 refrigerant are not compatible, their mixing at the gas station is rendering the conditioner.