Torsion beam is a form of suspension in which the role of the elastic element is played by a torsion. Torsión is a metal elastic element that works on a twist. This element typically consists of a set of rods, plates, or beams of a particular section. The latter shall be secured to the guide-lever and the other end to the frame or body of the motor vehicle. A firm link between the body and the wheel is achieved thanks to a torion. Torcions are used in various forms of suspension: on longitudinal levers, suspension on double transverse levers and so on. A similar principle has been applied in the design of the beams (suspension with related levers of right and left wheel). In view of the strong link between the wheels, the widest distribution was found in the rear suspension of the vehicle. To date, it is possible to say that the suspension of the rear wheels on the basis of the beams is the most common design.

The Torque Torque is a complete steel part of the complex configuration, rigid at the bend, but it is a curvature. This allows the wheels to move down and up independently of each other. The Torque beam is secured to the body, usually through flexible tulls. The wheel itself shall provide a constant distance between the wheels in the transverse direction. The extra elastic elements in the front beams are most often springs.

History of the construction and development of the [ [ Torque]]

History of the construction and development of the [ [ Torque]]

The prototype of the current beam is a torcion device, which was first used in Volkswagen Beetle in the 1930s. The Czech professor Ledvinka and the German inventor, Ferdinand Porsche, who adapted it for the first time for mass production, were involved in further improvement of the torsion suspension.

The rather broad application on small-liters of torsion was obtained in the 1950s and 1960s. The reason for the interest in the device is the relative ease of manufacture and the compactness of these elements. Towards the ends of the torchion, the longitudinal rocker levers were attached, which were connected with the turning fist by means of ball support poles or a pulley hub.

On the Zaporozhetz car, two square-cross-sections were used as the front suspension, which were placed in steel pipes located at each other, and the longitudinal levers of the suspension were fixed to the ends of the pipe. The author of this construction was the same German engineer, F. Porsche.

Unit and principle of the beams

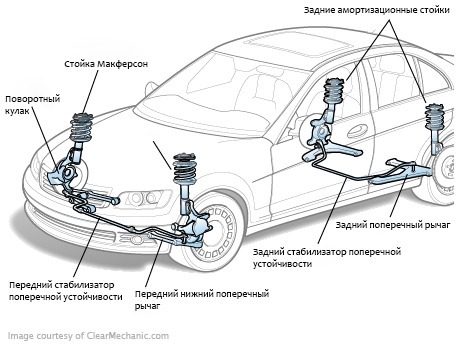

The guidance device with a torsion beam is the two longitudinal levers, which are rigidly connected to each other. On one side the longitudinal levers are fixed to the steps of the wheels and from the other to the body. The Torsion beam has a U-c-section, which means that it has a small hardness on the circling and the curvature of the curve. This property allows wheels independently to move up and down.

In modern cars, a torsion beam can be arranged in a transversally or longitudinally. The list of locations is used for passenger cars. And the longitudinal layout is common to large and heavy trucks. In both cases, the forward suspension ensures optimum attenation of the wheels and the bodywork, makes the move smoothly and regulates the heeling at the turn.

On some vehicles, the forward suspension may be used in conjunction with an electric motor while in an automatic mode. Depending on the condition of the road surface and the speed of the movement, this electric motor is pulling the beams to obtain the necessary stiffness.

Pros and cons of a beam

The main advantages of torsion padders in general are compactness by the width of the car, ease in regulating the height of the ground clearance, small total mass and, of course, durability. The suspension signs are very simple in maintenance and operation. Such suspension is much easier to regulate than the spring-loaded. From the point of view of the manufacturers, the market beam is cheap in manufacturing and is easily installed on the machine on the assembly lines.

One of the most significant drawbacks: extra vibrations from wheels on the body, which contribute to the low comfort of the rear seat passengers. As a result, it is impossible to make qualitative noise isolation, which negatively affects long distance trips.

Operational issues

If the torsion suspension on the vehicle is loose, it can be adjusted by a simple wrench. For this purpose it is necessary to get under the car and tighten the bolts. The main thing is not to overdo it, because the bolts when the car moves will cause excessive stiffness.