Variator, or in English, CVT ("continuely variable transmission") is a variation of automatic gearshift boxes. Appointment

Appointment

The purpose of the variator is to "smooth over" gearshift, although there is no failover itself. The variator changes the gear ratio as the vehicle disperses or stops, and makes this smoothly and inappreciably.

Device and operating principle

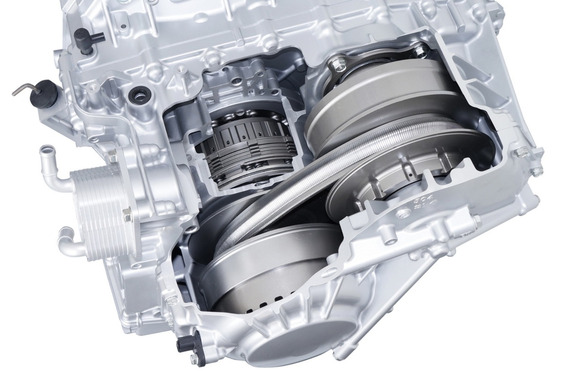

There are many types of variatorians, but the most common type is a pariant. It consists of two pullees, each consisting of two conical disks. The diameter of the pulley can be changed by the fact that the disks move and move. Disk movements are driven by hydraulic pressure and the spring load. There's a wedge belt between the pulsans. When the bend radius of the leading (closest to motor) and driven (leading to the wheels) of the pulley is changed, the gear ratio shall be changed. When the car starts, the leading sheave has the smallest diameter of the conic disks. And the slave, on the contrary, has the greatest diameter, the conic disks are compressed. The increase in the diameter of the leading pulley and therefore the reduction of the D-driven pulsation increases the speed of the output shaft and the speed of the car. This reduces the number and decreases the ratio. Next, the variance is maintained at the optimum level. In the case of a gas pedal position, the engine shall be operated at large speeds throughout the acceleration. This will take less time to disperse and the machine is not "twitching" as it does when gearshifts.

The variator is connected to the engine by a torque converter that ensures high transmission of torque and, respectively, the endurance of the gearbox.

There is no back-turn node in the vararator design. Therefore, a planetary reductor is used with the option-the same as in cars with ACPR.

Now the very design, the most important role in which the belt is played. It is a steel strip, or a set of steel tethers with a complex cross-section. It's called a typo, because there are a lot of thin cross-plates that have been made from steel on these sections. The belt can also be a steel chain in which the pin is in contact with the edges-such a type of belt is characteristic of German assembly cars.

To protect the chain, a lubricant is needed that would change its phase condition at the point of contact of the belt with pulley.

The fundamental difference between the CVR and the standard IBC is that, in the second case, the driver switches the gear when the engine has reached the required speed. At the same time, the variation shall only change the gear ratios and the engine speed may be kept at one level.

There are also options for which you can select the "virtual transfer" mode that specifies the electronics. Such a variator would shift the gear like a normal ACPR.

History

As for the idea, it belonged to Leonardo da Vinci. However, the mechanism itself appeared much later-it was only registered at the end of the nineteenth century.

The first car, which received a continuously variable Variomatic transmission, became the DF-600-a small Dutch production, which came out in 1958. In the late 1970s, the DAF was purchased by Volvo, which had to use the heredity of the variatos for the benefit of the savings. Thanks to the efforts of the Swedish company, the device's resource increased almost threefold and amounted to 30,000 kilometres of mileage, which the variant needed to replace the drive belt.

In 1984, Transmatic was introduced. Unlike a Variomatic with a rubber belt, which was extremely unreliable, a chain metal belt began to be used. Such variatas were installed on Fiat and Ford cars.

In today's world, producers have different names for the construction of their own variaitators. For example, Toyota uses the Multimatic varicaoris the same CVs and the Honda. The "Mercedes" variations are called Autotronic, and "Nissan" are called "Xtonic" or "Hyper".

"Toyota Prius" hybrids is part of a complex Hybrid Synergy Drive.

Advantage and disadvantages

The advantages of the variator before the ACPR are a relatively small fuel consumption, a fast speed set as well as a low level of harmful emissions into the atmosphere.

However, the variator has a number of drawbacks, the first of which-modern CVs are unlikely to work in pairs with powerful motors. This is why automatic gearboxes with variatos are equipped with the most common cars of small, rarer-middle class. Another disadvantage is maintenance and repair. The case of the variant requires replacement after hundreds of thousands of kilometres of mileage, and also requires a transmissive liquid and oil that is appreciably more expensive than the one that fits with the usual "machine gun."

The important factor is that the work of the variator depends largely on the signals of the sensors: the location of the wheel, speed, pressure and ABS. If one of them fails, it could disrupt the operation of the transmission.