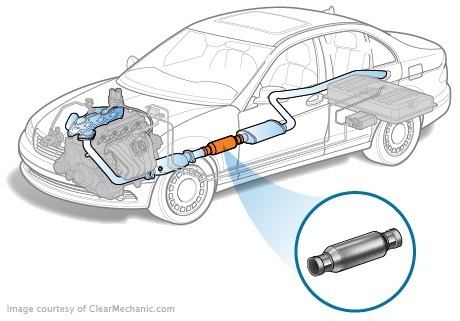

The main task of the resonator is to extinguish the sound vibration of rheumed exhaust gases from the combustion chamber. The size, shape and design of the resonator directly influence how loud the engine will operate. When this feature is broken, the entire exhaust system is not functioning. The car becomes noisy, the smell of the exhaust enters the cabin. History of the resonator in the exhaust system

History of the resonator in the exhaust system

The first resonator appeared on the car at the beginning of the 20th century. The decline in noise was the first task to be solved by developers, as soon after the emergence of serial cars, the pedestrians were displeased with their excessively noisy work. The details of a full-scale exhaust system, which can be seen in modern cars, have begun.

Working principle of the resonator

The exhaust gases shall be formed in the combustion chamber and shall be removed from the cylinder through the valve. After that, they are moving at high speeds on the exhaust manifold and on the receiving pipe. At the same time, the temperature of the gas mixture is about 650 degrees Celsius, so the exhaust system is exposed to serious heat load.

It's harder to create a resonator structure for a sports car. On the one hand, it must pass through itself the flow of gas without creating obstacles. On the other, reduce the noise level

The gas flow goes to the catalyst and then into the resonator, which is the cavity with one or more compartments. The chamber passes a pipe with small holes, through which a divided flow of gases passes. Passing through the pipeline facilitates the mutual absorption of sound waves.

Types of resonators

More sophisticated resonators may have a layer between the layers of which the insulating material is situated. Such details not only absorb noise, but also protect the body from heating.

Increasingly, combined rezonators, which are made up of two parts, are increasingly found in the car. The first part is based on a classic structure with a pipe and internal bulkheads and the other is filled with noise absorbing material (usually basalt fibre). Such combined resonators operate normally.

Operation and maintenance of the resonator

Longer is the resonator with the double hull. The material shall be corrosion-resistant. In general, cheap silencers for cars of the consumer market made of aluminized steel, that is, conventional steel coated with a thin layer of aluminium protecting the surface from corrosion. The resonator also plays an important role. The efficiency of its work depends on this indicator. If the volume is not enough, the noise will increase significantly during the pressing of the pedal, and the details can start vibrating.

By buying the resonator from the allure steel, it should be remembered that the low price of the product was obtained by reducing the durability. The best resonators are made of stainless steel.

As with any part of the exhaust system, the resonator is exposed to the harmful effects of aggressive factors: gas operations, high temperatures. Due to this, the length of service of the exhaust system is very small. Signs of breakage can be the intensification of noise, the smell of exhaust gases in the car, the presence of smoke under the bottom. In this case, it should be changed.

resonator in motorsport

Due to simplicity and low weight, the resonator is used in motorsport, but for this purpose the details are often subject to significant changes. As a general rule, sports vehicles are fitted with resonators with a more complex type of camera that provides sound absorption and has minimal resistance, that is, does not increase the backpressure in the exhaust system. Sports silencers do tend to make stainless steel, as it has a smoother surface (which produces a minimum of curing in the system), and the components made out of it work better in extreme temperature regimes.