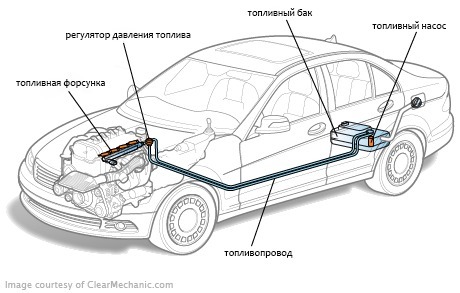

The cause of the smell of petrol in the passenger car may be practically any element of the fuel system. However, extensive repair practices have identified the weakest areas, which are the most frequent sources of gasoline smell.

The elements of the vehicle fuel system are distributed throughout the length of the body-this is done for safety to accommodate the fuel tank, which represents the potential danger, as far away from the engine as possible, which can be warmed up and down to the same electrical wires in the engine compartment.

A separate fuel system layout with only the minimum fuel necessary to continue engine operation in the engine compartment is its own minus: the fuel line is too long and there are too many compounds of different types. However, in 90 per cent of the cases, the leakage occurs where the fuel is the most-that is, from the gas tank or an element fortified or placed close to it.

General rules for self-discovery of fuel leakage

Since most of the fuel is stored in the tank, it is from the tank to start an inspection. The tank consists of several elements connected together in different-welded seams, composite structures, flanges and so on.

As a preventive measure, it is necessary to check the condition and thrust of the tapes from time to time, with which the tank is secured to the body

The tank may contain up to 100 litres of petrol of large weight and the tank itself is attached to the body (such a type of attachment is more common than the installation inside the trunk). Typically, the suspension is a flexible steel strip that is missing under the bottom of the tank. The tapes are drawn to the body with powerful bolts, and it is understood that it must be unwielable, but in fact it can rub against the body in case of strong tremors. Manufacturers provide this opportunity and make the gaskets between the body and the tank, but in the process of operation they are gradually wiped out and the tank has been gaining a small but steady movement which may eventually lead to the formation of holes.

In addition, the tank may be affected by corrosion. This is often the case with old cars.

If the tank was to be replaced or rusted, it should be replaced and, as a preventive measure, the condition and thrust of the tapes should be checked from time to time and fixed to the body.

Tank filler

The weak spot of the tank is a filler throat. It can be bolted to buckled through a rubber gasket or welded. The first type of construction is more reliable, since the weld in the event of the weakening of the tank suspension may be destroyed quickly, and the flange with a large number of screws will hold for a very long time, even if the tank will swing from side to side.

The welfoil compounds should be examined first.

Tied filler cap

The filler cap of the fuel tank shall be hermetically sealed the openings of the neck. The fuel should not only flow, but also vaporize through the lid, which is more difficult to achieve. There is a valve in the lid, through which the vapour can come out if the pressure inside the tank is increased (e.g. in hot weather). However, in violation of the tightness of the gasket, the gaskets will be released through it. In the vast majority of cases, the cover of the neck is sunk inside the body and the hatch is closed, so the pair will not be released into the atmosphere but in the car.

If the filler of the cover looks good, you should continue with the examination. If it's pluffed or skewed, the lid must be replaced.

Gas pump roof cover

There is a tank and another traditionally weak spot-the lid on which holds a fuel pump inside the tank with a fuel cell sensor. The old carbusts do not have a submerged pump, but the rest of the structure is the same.

Knowing the low points of the fuel system, you can successfully fight the smell of gasoline in the passenger compartment by carrying out an uncomplicated examination of the car

The cover is attached to the side of the side from the top with screws that sell into the holes on the contour of the hole cover. There is a rubber gasket under the cover: it is the weak link of the structure. The gasket is continuously affected by a pair of petrol from the tank, which during the years can destroy the rubber from which the gasket is made. This will occur sooner if the breakdown of the gas pump and the lid was removed and placed. The masonas are often uneven and then drawn by bolts. Even if the neatly laid gasket has not been broken, it may not ensure a leakproofness of the compound. In such a case, it should be replaced.

Rubber hoses

On the cap of the pump, there are tubes to which the rubber hoses are attached, between the tank and the bottom end of the fuel line. The tubes are made of rubber to allow independent movement of the tank against the fuel line. However, this is the weakness of the design-when the tube is moved on the lid may be broken or broken off at the base. This is often the case if a marriage was allowed to attach the patrons.

Valve of the petrol tank valve system

In general, in the same place, on the pump inlet, the fuel tank valve system valve is strengthened. For reasons of economy, the hull was made of plastic. The shell has a tube, also a plastic receptacle to which the hose is connected to the adsorber beam. The attached hose is not as heavy as rubber fuel hoses, but it can also break a fragile plastic tube. If this happens, you need to replace the entire valve.

There are still many elements in the subdued part of the fuel system that could be the source of the smell of gasoline. For example, fuel hoses are attached to the fuel filter. However, unlike the tank and its surrounding elements, the parts underneath the bonnet are in plain sight, and it is much easier to find the source of the smell in the engine compartment. However, knowing the weaknesses, it is possible to successfully combat the smell of gasoline in the passenger compartment by carrying out a simple examination of the car from the pit.