Evolution of the cylinders

At the dawn of the automobile era, when the designers were limited solely to the degree of their genius (or insane?) and the technologies available at that time, the internal combustion engines had a truly unusual form. For example, a 12-litre engine could consist of a single cylinder. Or eight to the next. There were even star-shaped aircraft engines under the hood!

In other words, unusual solutions, strange or just funny things were just the sea! But the struggle to reduce the cost of the car and to establish mass production has gradually spread all over their places.

With the growth of engine capacity and size, the question of how to make them compact was gradually raised. A classic average of four or six cylinders has somehow been used to restrain the car size, but what if the cylinders are 8? Do you have to get him to the subpotic space?

When the question arose as to how to shorten the ordinary engine, the solution turned out to be brilliant in its simple-"cruciform" it in half and adjacent to each other

The only relatively successful experiment with this engine location is the British AustinMaxi 2200, which was launched in the middle of the ' 60s. However, this was only 6-cylinder engine, the gearbox had to be hidden under the engine in order to somehow preserve the compactness of the car (the successor of this idea-Volvo S80 with a supercompact gearbox appeared in our time).

The emergence and development of a V-shaped engine

So it's not surprising that the question arises as to how to shorten the average engine. The solution turned out to be brilliant in his simple-"crucible" it in half, to put half with each other side by side, and make him work through one knee. These motors, shaped like the Latin letter V, are called V-shaped, and today they are one of the most common in the auto industry. The angle of the breakers is 60 or 90 degrees.

There were also the V-images with less breakdown. For example, the Lancia Fulvia car, which was launched in the 70s of the 20th century, installed the V4 engine with an angle of only 23 degrees. However, the design features of such engines and problems with too much vibration prevented them from being sufficiently distributed.

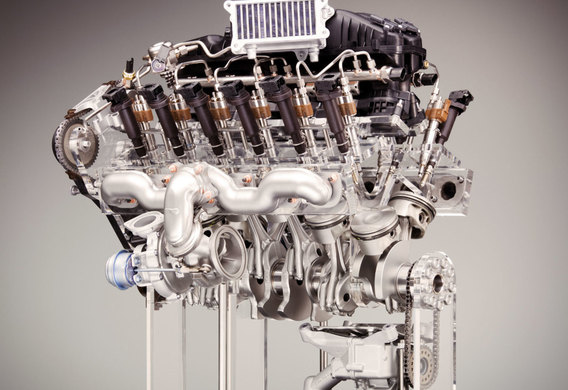

V-engine device

Such engines, naturally, are more complicated than that. They have two cylinders, each with its own gasket and a manifold, more crucible. Accordingly, their transmission pattern is also more complex.

The main problem of all VV-shaped engines is vibration and difficulty in balancing the mechanism

The only exceptions are the nil engines-they have one. But they were installed mainly on old car models. Some modern representatives of the American automobile industry are the exception.

Otherwise, the principle of action and movable parts is the same as any other internal combustion engine, be it a straight or oppositic engine.

The main problem of all VV-shaped engines is vibration and difficulty in balancing the mechanism. But this problem is almost completely absent in V8 engines with eight cylinders. The design of this type of engine is almost completely balanced by the system and eliminates the vibration, unlike the V6 engines (with 6 cylinders).

In general, engines of this type were created solely to increase compactness, so the question of the balance of the system of their creators was not particularly agitated. Today, it is being addressed by the irate of different parts of the engine.