The car is driven by the propulsion engine-the engine. The energy needed for the movement is selected from the rotating engine crankshaft, but it is impossible to pass the energy directly to the wheels-they will be spinning too fast and the car will not be managed. There are two devices, a gearbox and a bridge gear, to reduce the speed of the transmission.

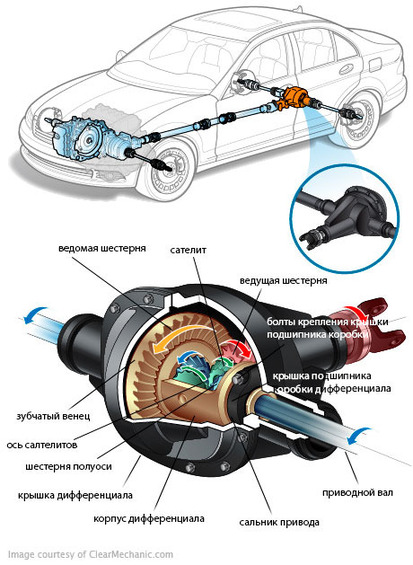

It would seem that the speed of rotation of the crankshaft would be sufficient to reduce the speed of the crankcase. In accordance with this principle, there is no motorcycle-cyclic transmission. However, the car is different from the motorcycle by having two leading wheels, so it is necessary to have a second device that rotates one of the two rest of the rest of the shaft.

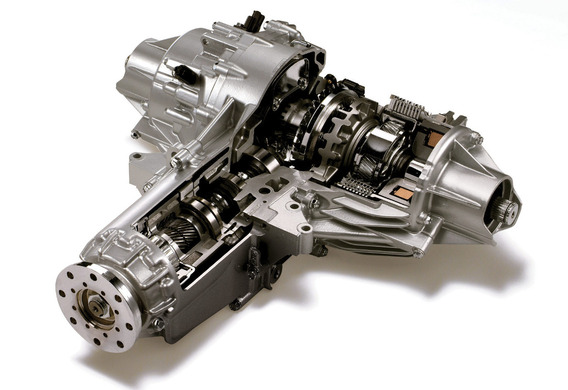

Stricter, in the case of a node, which is commonly referred to as a reductor, there are two devices hidden. The first is the gearer himself. The second is the differential that distributes the torque in the right proportion. The gearbox task is to reduce the speed of rotation of the output gross to the input. A retractor that converts a high angular velocity of the input shaft to a lower one is usually called a demultiplier.

Gear ratio of rear axle reducer

Rear-axle redeers shall be classified into the so-called gear ratio. The ratio is the ratio of the angular velocity of the leading shaft to the angular velocity of the driven shaft.

The higher the gear ratio, the higher the loading capacity of the vehicle

In practice, it is important to know only one thing: the higher the gear ratio, the greater the load capacity of the vehicle. Therefore, the lower the gear ratio, the car will go faster. It is important to know this because the same model, in different modifications, often puts pressure reducers with different gear ratios. For example, the reductor of VAZ-2102 in a universal station wagon had a number of 4.4 and a gearbox with a gear ratio of 4.3 was placed on the passenger VAZ-2101. This means that in one gear the gear of the gears on the output shaft of the gearbox each of her teeth will enter the cordon with the leading gears and leave it for four whole three tenfold. The same pattern can be observed in the construction of any rear drive vehicles, such as BMW.

Reversing rear bridge gear design considerations

In order to pass the torque from the leading shaft to the right angles to it, the shaft of the shaft shall be either gears or jagged wheels. Since the rampart is at different angles, the gears of the gears have a specific shape-these six are called conical ones.

The use of conical gears is due not only to the need to transfer rotation, but also to the fact that this type of jagged wheels produce less noise at work, which is important for comfort in a small passenger car.

In order for the reductor to actually be a mechanism that lowers the speed of rotation, it is necessary that the gear wheel drive be different in size from the driven wheel. If this rule is met, one full revolution of the incoming shaft shall be reduced or a turnover of the sub-unit shaft is reduced, thus the speed of rotation is reduced, that is, decreasing. Some cars require a very significant reduction in speed of rotation-for example, in lucky vehicles, which in some situations move very slowly to avoid getting stuck.

Rear-end-bridge redesign considerations

At the work of the killing, the gears come into contact with each other, that is, they are part of the cordon and come out of it. No matter how well chosen and regulated by the gears, the work of the killing is still worn out. So the gears are made of high quality hardened steel, and the gearbox is filled with liquid transmissive oil. Oil has a tendency to flow and hold it in the seal of the exit of the gross. These seals are called sappers and have a limited service life. When the scurl is worn, the oil marks appear on the body at the exit of the gross. If they do not replace them in time, the oil will be replaced by the oil, and its wear will be repeated many times. In addition, the dirt falls through wornout compaction. To prevent this, the gearbox must be inspected periodically from the hole.

Rear-end gear casing

The Hull Corpus is an entirely indistinguishable metal. The method of casting is good in that the detail obtained by its assistance has a high durability, which is necessary given the difficult conditions of the retractor's operation. It's pouring out the bodies most often from a pig iron. Minus the cast frame is a large weight. Therefore, if it is necessary to facilitate the weight of the gearbox (for example, to be installed in a sports car), the shell is removed from a light alloy, adding to the foundry only places with direct load.

What other drive constructions are used by the rear tractor gear reducer

The rear bridge retractor is available in all rear wheel-drive vehicles, for example, in the "classic" VAZ models, such as 2106. Apart from the rear-wheel-drive vehicles, there is a rear bridge retractor in any four-wheel-drive SUV, crossover, off-road or sports coupe. By the way, in four-wheel-drive renters, at least two-rear and front bridges.