The name of the "Jackass" is of direct relevance to the nature of the work being performed-the transfer of the reciprocating motions of the piston to the crankshaft. The most notable distribution was in the era of steam locomotives, which were part of the transmission. When a return movement is made, one end of the case is moved up and down with a limited amplitude, that is, "shaky".

Shaun is one of the most ancient details of the mechanisms. This feature can be seen, for example, in the design of the apparatus of the genius engineer Leonardo Da Vinci

Shatoon is one of the most ancient parts of the ancient and wooden mechanisms. The first known jackets worked in the construction of the Roman mill of the third century. They turned the rotation of the water-powered wheel into the back and forth movement of the saw. For the first time, a combined crankshaft is seen in the construction of the water pump of the twelfth millennium, invented by Arab engineer Al-Jazari. Its construction was not similar to the modern cryopohic mechanism and was much more complex, indicating that the Al Jazaari did not fully represent the law of energy conservation. In Italy, the age of the Renaissance design with the use of the shauna can be seen on the canvas of the artist Pisonello depicting the water pump's work. By the sixteenth century, the construction of the crankshaft was finally adopted and widely distributed. This is contained in the pages of the "Theatre Machinarum Novum" of 1588 by George Andreas Bokler, which describes at least 45 cars built with the use of a shauna.

Brass device

The engines of modern automobiles use the caps made of steel, but other versions of the material are also encountered. For example, for sport vehicles engines, titanium or special high-temperature aluminium alloys (T6-2024 and T651-7075) may be constructed. In addition, sportspeople are distinguished by the method of production-they receive a method of forging that strengthens the structure of the metal. Cated pistons and jackasses are stronger than usual, received by the method of casting.

Shatonys-mandatory replacement for major engine repair

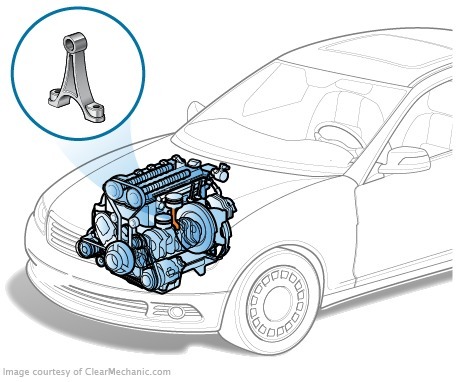

Shatunas are arranged in such a way that none of their ends are attached to the adjacent components so that friction is created. Through the upper head of the beetle, the piston is extended to the piston, to which the piston is attached, and the lower head is put on the neck of the rotating crankshaft. Of course, both fastenings imply the use of abundant lubrication. In order to reduce the wear of the crankshaft neck, the lower head anchorage shall be provided with special liners which have anti-frictional coverage.

The lower "loop" of the Jackass, through which it is attached to the shaft, makes the lower part of the "rings" a so-called "ring"-the so-called "cap"-can be separated.

Special features for the operation and repair of the Jackass

Despite the fact that the jackasses do not form frictions at either end, defects of the jackatoms occur in practice very often. The problem of the Jackass is not about friction, which is almost not (except for the friction of the side of the knee), but at the load and in the high temperature. The load on the Jackass, which is multidirectional, can reach several tons, and sometimes several tens of tons. This is the peculiarity of his work is that the shatoon is compressed in a shift, that is to stretch over the course of one full cycle, that is, the shaft turn. As a rule, when the tap of stepped-on inserts, it is customary to replace only the inner liners, although as a result of the overheating of the engine or the cranking of the liners, the Jackass is almost certain to be deformed-warp. To understand whether the axis of the heads is parallel and does not curve the head, you need to make measurements with special devices.

One of the most impressive engine breakdowns is a hole in the cylinder block that has been flutting out

In addition to being a frequent defect, the hole in the top of the jackass is worn, into which the so-called "floating finger" is inserted. To determine whether a flat hole or it is broken can only be set to zero, because the visual inspection will do nothing-the size of the wear is too small.

To determine the amount of deformation-the cause of the non-oseness-a slab can be put on a span plate-a perfectly level surface to judge whether a part is deformed or not.

How to Repair the Jackass

The diameter of the bottom hole after the washings of the liner shall be increased and shall be restored to the nominal size of the plant. For this, the cap is first "understated" by a small amount measured in microns-approximately 0.05 to 0.1 mm. If it's a bad thing, the lid is slick if they're milling. Naturally, after the underestimation, the hole loses shape and should be squinting. In addition to the return of the form, the wasteful form helps to restore the factory size of the hole. This operation uses a special ratel for the caps, but if it is not present, a qualified car can do the same with the help of the special snap-in on the universal machine (top-milling). After the waste of the wall the opening is ideal for the condition of the chonings (the same treatment is carried out by the cylinder wall at the refraction of the block). Modern engines generally fall into the category of high-force, as the modern automotive industry has a marked increase in output without an increase in the working volume. To do this, various units are used to increase the compression ratio when the volume is stored, for example, by turbochargers. Naturally, when the load is applied to all without exception, the details, including those on the jackasses, are increasing significantly. Consequently, with the slightest disruption of the operation of the lubrication system, there may be irreversible consequences for the caps. With great overheating and heavy loads in the structure of the metal from which the caps are made, such changes occur, that the repair of the jacktuns may not be possible or too expensive, and it is easier to replace them with new details.