The piston is the part of the piston group of the engine within the cylinder. The piston is connected to a crankshaft with the help of the Jackass. The design is designed in such a way that the piston during engine operation is continuously driven by a back and forth motion, converting the energy of the expanding gas in the rotation of the crankshaft. Portion piston

Portion piston

The piston is made up of three parts, although it is done from a single piece: the bottom, the bottom compellant, and the skirt. To the crankshaft, the piston is joined with the help of the Jackass. The piston is placed on the shaper and is fixed by a fleshy finger, through the part. The shape of the bottom of the internal combustion engine is never flat. Depending on the design, the bottom may have a complex configuration. Candles, injects and valves may be located above the bottom.

The distance from the bottom of the piston to the first compression ring is called a piston belt

Most often in the bottom of the piston a cavity can be seen to ensure that the valves moving above them are not in contact with the piston surface. Deepening is generally of great depth from one edge, as the valves above them are located at an angle. In general, the general form of the bottom is generally concave. This is because the piston, rising up, is simultaneously the day of the combustion chamber, and for the optimal propagation of the flame, the concave is as good as possible. This form has its drawbacks-the bottom of the inundation is faster than the tanning.

The distance from the bottom of the piston to the first compression ring is called a piston belt. Since the piston works in extreme high temperatures, the firing belt has a calculated height that depends on the material from which the piston is fulfilled. Reducing the height below a certain limit may result in premature promotion of piston.

In the past, the piston was made entirely of steel, but in modern engines, lightweight pistons of aluminium alloys are often used

The piston is very precise because one of its tasks is to serve as the basis for compression rings at the time of compression. Over time, the piston is worn and burned, resulting in reduced compaction-hot gases start to seam between the body of the piston and the ring, and enter the crater, and the oil is sewn into the combustion chamber.

It follows that the increased oil consumption may be a sign of wear on the piston. In addition, it is possible to judge from the smoke in the exhaust stream the smoke is generated by the burning of the oil over the area.

The combination of the bottom and the compacting (the basis for the rings) is called piston head. In the past, the piston was made entirely of steel, but modern engines often employ lightweight aluminium alloys. Aluminum cedes strength, so to create the foundation for the upper compression ring, it is supplied with a rim of high anti-crust and characteristic iron. In a cast-iron shodle, floating in the body of piston, cut the groovy wire into which the upper compression ring is inserted. This type of pig iron is called a niresistie.

In the lower part of the head there are channels for the oil rings. They shall be cut at the machine and supplied through the perforation, through which the oil is removed from the mirror of the cylinder at the inner wall of the piston in the pan of the cylinder block.

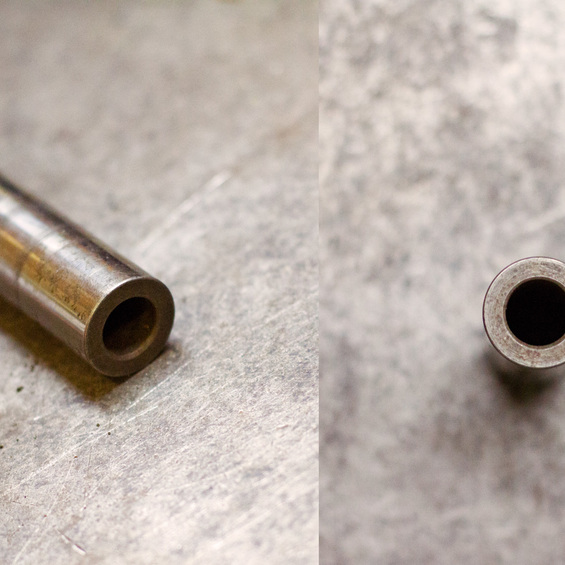

The sponge or guide part of the piston is equipped with two tides, or the filmmaking holes for the fitting of a piston finger. Since the pistachio is thicker in its location, it is most likely to be deformed due to temperature. In order to avoid the risk of deformation, part of the metal with the chips is cut down on the milling machine. The clerks for cooling and increasing the intensity of lubricating of the dredging are referred to as technical slang "refrigerators". Materials for piston production

Materials for piston production

The materials used for the manufacture of pistons are presented with high requirements. First of all, the material must be of high mechanical strength at low density and low ratio of linear expansion, high thermal conductivity and cordiality, good anti-friction properties. From this, the pistons are made from either grey cast iron or aluminium alloy, often with an injection of iron.

The chun pistons are strong and durability, working with small gaps. The lack of pig iron is a big weight. Therefore, the cast-iron pistons are generally used in low-bearded, well-balanced engines. The cast has low heat conductivity, so the bottom is heated. This is a disadvantage because the high temperature inside the combustion chamber can result in the incorrect combustion of the fuel, which is called a potash ignition. This problem was particularly acute in previous years when the dominant injection device was carburetor.

More often than not, aluminium alloy pistons are used in modern engines. Their advantages are low weight, high thermal conductivity (thanks to which the bottom temperature is rarely above 250 ° C). It was due to this factor that engineers were able to find a way to significantly increase the compression ratio in gasoline engines. Main downside of aluminium is a large coefficient of linear expansion, which causes large gaps, reducing the ability of piston to seal. In addition, the mechanical strength of aluminium at heat (up to 50%) falls, which does not happen to pig iron. However, the shortcomings were not fatal, as engineers managed to think of ways to negate the negative properties of the material. For example, to reduce the loss of compression, the skirt of piston is attached to the oval form. In order to avoid the deformation of the overheating, the skirt is isolated from the head with material with low heat conductivity and tp.

Interesting piston facts

The most "strong" pistons are forged, that is, made from stub methods obtained by the method of casting and subsequently subjected to the carrot. Covka-Mechanical processing of heated metal to heat. For each metal there is a coking temperature; aluminium is not high-just 500 degrees.