The engine cooling system was very popular after World War II, when people did not have money to buy expensive cars. A simple and reliable system, built on the forced airflow of the heated block of cylinders, has proven itself in low-power micro-tracts of European manufacture. Air cooling targets of the engine

Air cooling targets of the engine

For internal combustion engines, the temperature of the individual parts may increase to 800 to 900 degrees and the cylinders are heated to 2000 degrees Celsius and higher. If the engine does not cool, its capacity will significantly decrease, and fuel and oil consumption will increase. The motor overheating of the engine parts, in the same way, leads to rapid deterioration and breakage.

Until 2001, the [ [ Volkswagen Beetle]] engines were used in the [ [ Australian ski resort]] in the [ [ Thredbo]] ski resort

Excessive cooling is not less harmful to the engine. In the case of hypothermia, the same symptoms are observed: reduced capacity, accelerated wear of the details, increased fuel consumption.

In modern cars, the chilling system also performs a number of secondary cooling tasks. First of all, this is heating air in the heat of the passenger compartment. In addition, the refrigeration system often cools the engine oil, the working fluid of the automatic transmission, and in some cases the receiving collector or even the throttle.

In order to perform all these tasks, the modern cooling, air or liquid system disperses about 35% of the heat generated by the combustion of the fuel.

Cooling air system

The air-cooling medium is the airflow.

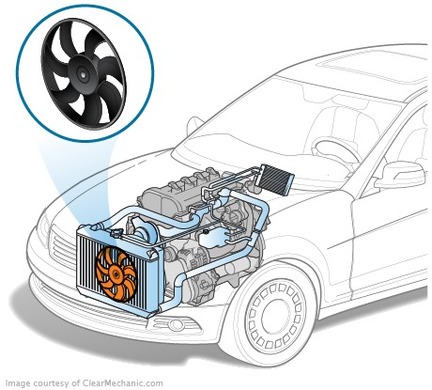

It dissipates heat from the cylinders, the head of the unit, and the oil cooler. The system includes: fan, cylinders of cylinders and heads (or heads), removable skin, deflectors and control devices.

Perhaps the most powerful air-cooled car engine was installed on Porsche 911 (933) Turbo S in 1997. This dual turbine engine developed 400 horsepower

The block and head of the air-cooled engine cylinder shall be fitted with additional ribs that increase the surface of the surface in contact with the air. The air flow is forced to the engine casing, by a fan with blades of solid but light aluminium alloy.

Air cooling fan design

The ventilator is the main node of the system and the fan of the fan is the main part. Engineers have thoroughly calculated the shape and design of the fan parts to optimize the air flow. It consists of a guide and a rotor, usually consisting of 8 shoulder blades radially.

In the sending machine, the diffuser is the broken section of the variable section, which is used to direct the flow. They are immotionless and equal in the circumference of the circle.

The air-cooled engines were placed on the Czech company Tatra's four-wheel-drive trucks

The rail of the steering apparatus changes the direction of the airflow, forcing it to move towards the opposite rotation of the rotor. This increases the air pressure and therefore the cooling of the engine.

The fan is driven from the pulley of the crankshaft by means of a belt. The driving machine is fixed to the engine.

The ventilator is equipped with a safety net to prevent foreign objects from reaching the rails.

How the Air Cooling of the Engine works

Since the cylinders and their heads are heated more than other parts, a powerful airflow is dispatched, first of all, along the channels between the cooling ribs. The air is then equally distributed to all the details of the engine by means of the deflection guides-thin metal plates.

The air flow of the fan to the cooling system is about 30 cubic metres per minute. This ensures the normal operation of the low power engine and a small volume in the temperature range from -40 to +40 degrees.

The engine cooling rate with the air system is controlled automatically by thermostats and races.

Advantages and disadvantages of air cooling

The advantage of the engine cooling air cooling system is the simplicity of operation, maintenance and repair.

Air cooling makes it possible to significantly reduce the mass of the engine and ease the cold start.

The deficiencies of the air cooling system have been taken to include increased engine size and noise levels. In addition, in such systems, some elements have high heat load due to unevenness.

Air-cooled engines are more sensitive to fuel, lubricants, and spare parts as they operate in a more extreme operating mode. In addition, it is necessary to carefully monitor the purity of the engine compartment, as even the thin air raid on the engine casing significantly reduces the cooling performance.

Features of the engine air cooling system

An indication of the poor performance of the cooling system is the increase in the temperature of the oil in the engine crankcase recorded by the special sensor.

The most common breakage of the air cooling system is the fan of the fan. On the dashboard of vehicles with an air cooling system, there is a lamp that signals this malfunction.

Engine air-cooling

The application of air-cooled engines in the automotive industry came in the sixtieth centuries of the twentieth century. During that time, the world produced the maximum number of vehicles with an engine cooling capacity. The Volkswagen Group models are known as the famous "Zhuk", Transporter T1 and T2 and others. The models built on this engine were built by American engineers from GM (Chevrolet Corvair), French (Citroën 2CV, GS and GSA), and Japanese (Honda 1300). A separate mention is made of cars with engines of air cooling of another German concern-Porsche. One of the most famous models produced by Porsche 911 has been equipped with air cooling for a long time. Thanks to the genius of Ferdinand Porsche, only the company's vehicles were equipped with powerful air cooling engines.

Most of the excess heat is approximately 44 per cent separated from the engine through the exhaust pipe, regardless of the type of cooling system

In modern car manufacturing, air-cooling engines have lost their popularity. Maine as a result of the dominance of the front-wheel-drive models with the transverse engine location. In this design, first, it is difficult to organize an efficient air cooling system, and secondly, it is not difficult to install a water cooling radiator.

The Patriotic War also did not bypassed the popular concept by the party. All vehicles from Zaporizhzhya plant produced during the life of the USSR possessed air-cooled engines with rear wheels installed in the rear of the body, according to the same concept of Ferdinand Porsche.