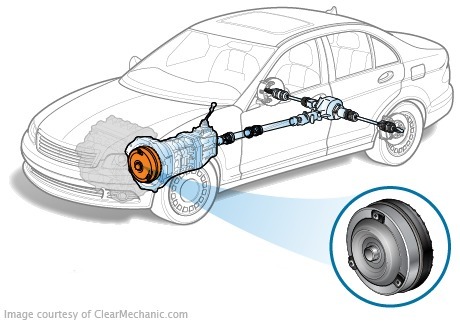

Both devices are used to transmit torques from the leading engine shaft to ACPR. In both mechanisms, there is no hard link between the master and sub-surface ramps, so they pass the rotation from one axis to the other smoothly and evenly, without any levers and shocks. History

History

The development of shipbuilding at the end of the nineteenth century is required by the birth of a hydrotransformer and hydromuft. With the arrival of ships in the fleet of steam engines, there was an urgent need for a new additional mechanism that would bring the steam engine torque to large and heavy propellers loaded in the water. Such devices were hydromuft and hydrotransformator, which was patented in 1905 by German engineer and inventor Hermann Feettinger. These mechanisms were later adapted for the installation of the London buses, and then to the cars and the first diesel locomotives for a smoother start.

Device and operating principle

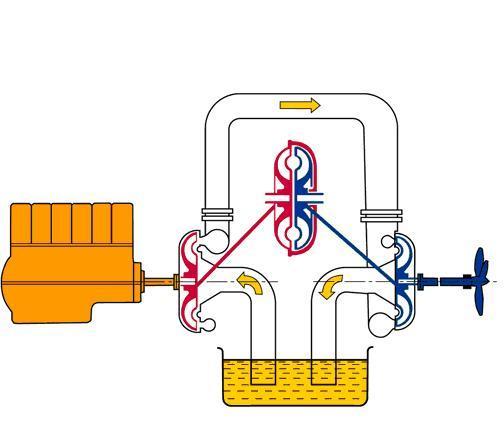

Inside the hydromuls, two rotating wheels with blades are located very close to each other. One is connected to the leading shaft (pump) and the second with the winged (turbine). All the space around them in the hydromuft is filled with fluid (oil).

The principle of hydromuff is very simple. Its leading shaft rotates with the engine. Oil is circulating with the shaft of the hull, together with the shaft. With its viscosity, it gradually becomes more and more involved in the rotation of the slave shaft. Thus, the engine torque shall gradually be transmitted over the liquid to the driven shaft.

Water converter design and operation principle

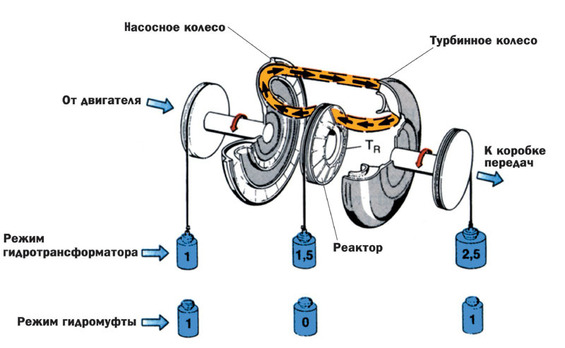

In fact, the hydrotransformer is the same hydromute in which the third blade reactor (s) is added between the rotating wheels. Through the free travel couplings it can rotate on the leading shaft, forming a single whole with pump wheel. This occurs as long as the rotation of the pump and the turbine are different. As soon as they are levelling, the reactor starts to spin independently of the pump, turning the hydraulic torque converter into the hydromuft.

Plus and Minus

The main advantage of hydromuft and the torque converter is the possibility of a smooth change of the torque transmitted to the transmission from the engine. Another important advantage of these devices is the limitation of the maximum torque to be transmitted. In other words, these mechanisms will never be able to pass too large a rotation that could damage the transmission. They shall be protected against overloading of the drive motor (especially at the time of the launch).

The biggest lack of hydro-transformers and hydrocouts in turn is low efficiency in comparison with mechanical couplings with hard links of the leading and driven shaft. Part of the torque is simply spent on the mixing of oil. Instead of turning into a net torque at the output shaft the power of the rotation shall be transformed into heat, heating of the couplings. Accordingly, this results in an increase in fuel consumption. To avoid this, modern cars with ACPR for transformers have a locking mechanism that rigidly binds the pump and turbine at a certain speed.