Haldex is a self-balancing, whisky-based, whiskered and electronic control.

The Haldex muft has been developing a known nearly a hundred years of the principle of viscous differential (malt) through the use of electronic components. After saving the main purpose of the differential, the idea of Haldex is a new step in the theory and practice of automotive industry. It is a kind of "smart" differential, which specifies parameters for the operation of the transmission, taking into account not only the speed of rotation of the wheels, but also the engine modes, brakes and auxiliary systems.

History of building the Haldex couplers

Haldex was invented in 1988 by Swedish engineer and former rally driver, Sigvard Johansson, who initiated the idea of automatic redistribution of torque among the vehicles in unpredictable conditions of the rally. In 1992, he sold his invention to the Swedish company Haldex, the specialists of which introduced it into the design of the four-wheel-drive transmission Quattro, realizing the concept of automatically attached complete transmission. In a vehicle with a full drive. Serial machines with Haldex have been released since 1998. The first was Audi A3 Quattro, Audi TT and VW Golf.

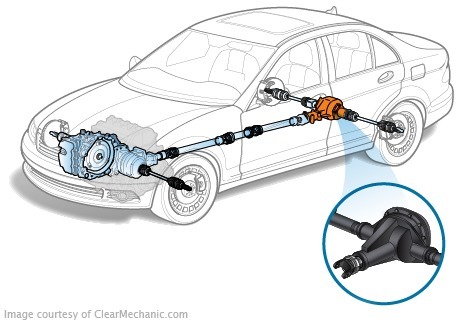

Device and operating principle of Haldex

On vehicles equipped with the Haldex coupler, the main part of the torque shall be transmitted to the front axle under standard conditions. The mechanical part of the coupler is formed by a package of friction disks which do not have contact with each other during movement under normal conditions. Half of the disks are connected to the rotor, the other is connected to the rear axle drive shaft. The body of the muff is full of oil. The preliminary oil pressure shall be set by the electrical pump. This is the first electronic component of the system that provides the minimum distance between the disks and, as a consequence, the engine's speed reduction. The working pressure shall be used for the plunger pump, which is based on the difference between the rotational speed of the input (the shaft) and the output (rear differential)). Increasing the base speed of the main driving pump increases the pressure in the system, and the force is transferred to the hydraulic cylinder, the friction disks. Thus, the thrust between the bridges is allocated as a percentage of the 100/0 normal movement to 50/50 with a total loss of adhesion on the front wheels. At the same time, the optimum distribution of the torque and the operation of the muft shall be achieved by adjusting the operation of the blower Pump to the receiving and processing units of the accelerator pedal position, engine shaft speeds and ABS and ESP control units. At present, vehicles with a fourth generation of Haldex motor vehicles are being produced. The first generation of Hadleks-innovative for their time, but far from perfect, was applied until 2002. In this second generation of devices, the second generation of the general construction of the muft was combined into a unit with a rear differential, and the electro-hydraulic module was introduced as a separate component, making it easy to replace it. To extend the interservice interval, the manufacturer increased the amount of oil. In addition, the electromagnetic valve in the system has been replaced by a hydraulic valve. This has increased the speed of the "recall" of the system to change the road conditions.

The third generation of Haldex received an index of PreX. Its main feature was the introduction of an even more productive electric pump and installation into the control system of the hydrocylinder of the non-return valve, which enabled the possibility of advance blocking of the muff of the electronics. As a result, the full lock cycle has been reduced to 150 milliseconds.

In the fourth generation, the design changes radically changed the behavior of the system. The fruit pump has been eliminated and the pressure in the muct system creates a powerful electric power pump. The transfer torque shall be specified by the control unit of the complete transmission with the coupler closure control valve. The muct is now fully driven by electronics and the difference between the wheels of the wheels of the wheels and the rear axle is not a condition of its inclusion regardless of the road conditions. The back main gear is now on permanently and the control unit receives information from the transducers of the transverse acceleration sensors, the longitudinal acceleration of the vehicle, the engine speeds, the accelerator positions, the speed of the wheels, the stop-signal switch and the steering wheel angle. The main signal goes from the pedal of the gas, and even with the normal acceleration of the muft is blocked not by the result, but to prevent wheel thrashing.

Haldex Add and Minus

The main advantage of the Haldex system is that the car, in fact, becomes a 4x4, but retains all the advantages of the front-wheel drive. At the same time, the system prevents increased load on the transmission during parking and maneuvering, and in any configurations is combined with ABS, ASR, EDS and ESP.

The shortcomings of the Haldex system include the mass of the volume of the luggage compartment that leads to the loss of the useful volume of the luggage compartment, as well as the fact that there are many electronic and hydraulic components that reduce reliability compared to purely mechanical devices. Many owners of Haldex vehicles also note a high probability of overheating of the mufti case while driving in the city.