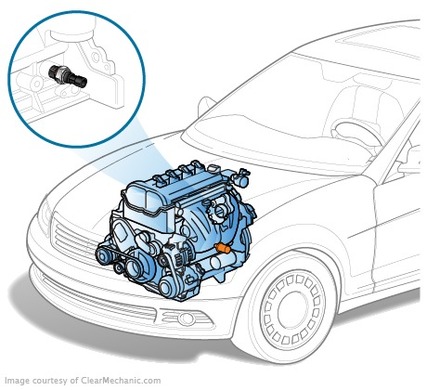

The oil pressure sensor is an instrument that converts a mechanical effort into an electrical signal of different voltages that, after decryption, allows for real time pressure to be measured in the lubrication system. Why do we need an engine oil pressure monitoring sensor?

Why do we need an engine oil pressure monitoring sensor?

The engine oil shall be fed to the engine by different means, including the spraying (for which, for example, holes in the preset, for example), which must be pressured.

In order to save money when the engine is in the car not having a standard oil pressure monitoring instrument, it is possible to purchase and install a budget instrument from a Russian truck

If it is lowered, which may be caused by a decrease in the amount of oil in the system or the failure of the oil pump, the friction of the knots increases, resulting in accelerated wear and tear in the details. To prevent these effects in a timely way, the pressure sensor is embedded in the lubricant system.

Reading a signal can be implemented differently. In most cases, the driver shall not see the detailed reading and can only be guided by the activation of the pictogram showing the oil on the instrument panel if the pressure is lowered to the critical level. In some vehicles, the engine oil pressure is displayed on the individual meter scale. In the most modern vehicles, the pressure sensor is used not only to control the condition of the engine, but also to optimize its operation.

Oil pressure sensor device

The work of most pressure sensors is based on the principle of converting one form of energy into another. Primary transformers issue a mechanical force that either has a direct effect on the sensing device's sensitive element (s) or is converted to an electrical signal. In modern cars, type two pressure sensors are used because the electrical signal can read and interpret the computer control unit.

Old sample probe device

A classic instrument on the dashboard of old vehicles (e.g. GAZ 69) coupled with a sensor is a variety of manometers. In the old sample, the oil pressure measurement was based on the deformation of elastic sensitive membrane (membrane). The membrane was pressuring the membrane to pressure the liquid in a sealed pipe. At the other end of the liquid, the liquid pushed on another shaky that raised the mechanical arrow. This is called a diphanometer.

Depending on the country of production, the oil pressure scale can be calibrated in Pascal, Newton by square meter, bar, atmosphere, or kilogram of force

Modern oil pressure sensor

In more modern models, the measurement is carried out by a transducer mounted in a cylinder block, and the readings shall be transmitted in the form of an electronic signal to the vehicle computer or to an electronic chart. To do this, there is an intermediate converter that turns the mechanical effort into an electrical signal.

In such devices, the role of the sensitive element is performed by a rigid metal membrane equipped with a resistor, changing resistance in response to deformation. The resistance shall be converted by the measuring system into an electrical signal which is transmitted by wire or via a CAN-tyre.

Operation of the oil pressure sensor

The engine oil pressure at idle speed shall be 2 bar. The oil pressure shall be in the area of 2 bar. The oil pressure at high speed (generally for most of the engines is 5500 mins) from 4.5 to 6.5 bar. If the pressure fluctuates within the acceptable range, the contacts in the electrical converter circuit are open and the low oil pressure alarm on the instrument panel is not lit.

The average oil pressure is affected by the height of the vehicle's location above sea level

In general, the oil pressure sensor is reliable and seldom operational. More often than not, it happens to the seal, which does not allow the oil to leak out of the cylinder block outside. It is necessary to keep track of it, as in the case of oil leak it falls on a hot block, which can cause a fire.

Reasons for the drop in oil pressure in the system

The pressure too low or too high is always a malfunction of the engine or at least the oil pump.

If the pressure is high, it may be somewhere in the system. It is possible that the oil canals in the wall of the cylinder block may be blocked, and possibly the pressure relief valve is stung by wear.

If the pressure is too low, it may be a reduction in the spring or the general wear of the oil pump.

Situations of incorrect pressure may be different, and they are not necessarily related to breakdowns. For example, when the engine is started, the pressure in the cold oil circulates may be normal and the temperature will drop to almost zero after the hot soak period. This is due to the fall of the heating oil density.